DESIGNED FOR USE IN ADVANCED REFRACTORIES

Global Alumina Portfolio

Our premium aluminas are specially built for advanced applications. These applications include monolithic, prefabricated pieces, bricks, and isostatic pressed products.

Applications

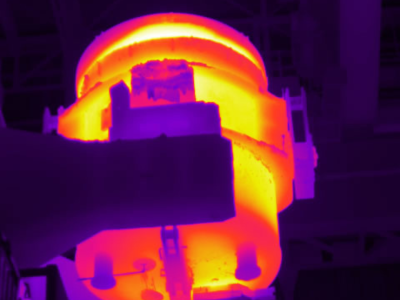

Refractories are special materials designed to withstand the harsh conditions of high-temperature processes that are fundamental to our daily lives. Vital to the efficiency, functionality and safety of countless industrial operations, refractories play an indispensable role in the production of iron and steel, cement, petrochemicals, non-ferrous metal, glass and other essential products.

We offer cutting-edge refractory solutions with an expansive alumina portfolio, recognized as the broadest of its kind worldwide. Our premium aluminas are specially built for:

- Monolithics

- Prefabricated pieces

- Bricks

- Isostatic pressed products

We offer advanced refractory solutions with standardized products all over the world.

Our premium aluminas are specially built for advanced applications. These applications include monolithic, prefabricated pieces, bricks, and isostatic pressed products.

But we do not stop there. Our resources become solutions for high-performance refractories, where heat tolerance, creep resistance and corrosion resistance are of utmost importance. For us, performance is not just an objective; it is the core of our dedication to excellence.

We are proud to feature a wide selection of synthetic alumina aggregates, available in a variety of crushed and milled sizes, and strategically crafted to optimize refractory formulations.

Think of aggregates as the backbone of refractory formulations, endowing dimensional stability to the final products. The coarser fractions contribute to heightened thermal shock resistance and robust corrosion resilience.

What sets our alumina-based aggregates apart is our steadfast dedication to utilizing high-purity raw materials.

Guided by rigorous production protocols, our aggregates emerge as inherently pure and homogeneous, establishing the foundation for the creation of sophisticated, high-quality refractories.

In addition to aggregates, we excel in providing high-performance matrix products, which play a necessary role in optimizing particle size distribution and increasing refractoriness.

The result? Ultra-fine aluminas with high sinter reactivity provide enhanced mechanical strength and abrasion resistance, contributing to the longevity of refractory products.

In monolithic formulations, we take a strategic approach, combining reactive and dispersing aluminas for efficient castables with impressively low water demand and setting control—efficiency and performance in one intelligent package.

Incorporating high-temperature calcium aluminate cements and binders, we bolster stability, underscoring the expertise and dedication embedded in our comprehensive refractory solution.

At Almatis, we stand out as a reliable partner for those who prioritize a holistic approach to execution and longevity in demanding industrial environments.